Oil testing kit Blog

Oil Testing Kit Public Beta Program - Welcome!

We've had a huge response for our call for help in the Oil Testing Kit Beta Program from a couple weeks ago, and today we're ready to announce our selection. These 20 people have agreed to participate in the first public beta of the OIl Testing Kit by posting documentation of their tests as well as their raw data to troubleshoot the procedure and setup.

Some applicants posted great reasons why they're interested in the kit. Just a few excerpts:

- "...over recent years we have suffered from oil pollution on our beaches after ship wrecks and also oil spills at a oil refinery on the river Loire who's estuarie is near our beaches. We sometimes find black residue on rocks and I would like to be able to test these and also water samples around our area."

- "We have been looking for just such a way of consistently testing samples from locations in and around our bay... both where we suspect legacy petrol-based waste dumps and spills, and to examine new spills."

- "Vancouver recently had an oil spill happen right in the city waters, and months later there is still black crusty stuff on the beach which no one seems concerned about. "

We have a lot to do before we can get to testing some of these scenarios, but the Beta Program is intended to refine and improve our test so that we can do rigorous and credible testing soon!

So without further ado, by username, we'd like to welcome:

- cquijano84

- Tofu

- ronhuber and norby (together)

- uprmotero

- Craig

- tmccaffr

- Charles_Hamilton

- mahsa

- JayB

- MelissaN

- LKStendie

- wsg

- zhughbanks

- JeanellSullivan

- Webstertiums

- emilycheung17

- ethanbass

- Cindy_ExCiteS

- chongyukwai

- drocheleau

We'll be announcing a quick meetup session in a week or so where we'll outline some of the specific responsibilities participants will have, and be available to answer more questions.

If you weren't selected this time, don't worry - we anticipate a broader release pretty soon, so you won't have to wait long to get your hands on a kit. We are very eager to get you all kits and to grow this important effort.

Congratulations to everyone!

Follow related tags:

spectrometer oil-testing oil-testing-kit homebrew-oil-testing-kit

Silhouette Cameo desktop paper cutter for prototyping

What I want to do

I've been wanting to do more laser cutting to prototype things like the Oil Testing Kit, but it's a pain to go all the way over to the llocal shop at Danger Awesome for small parts. And laser cutting leaves ash and smells bad.

I've had my eye on these craft oriented cutting machines for a while but after not looking at then for a couple years I was surprised to learn how cheap they are. The Silhouette Cameo is only $240 on Amazon! So, I ordered one. It arrived today.

My attempt and results

I need scoring as well as cutting, and the Cameo does that by cutting a dashed line at partial depth. Here's a good tutorial.

Getting the cut depth and blade settings took a few tries but it works really well! The free software reads .dxf files, and a $50 upgrade gets you .svg import.

Questions and next steps

It couldn't cut through very heavy cardstock, but maybe I didn't set the cut depth properly; I'll try again. Size was also not well preserved in dxf import, but re-entering the dimensions was easy if annoying. Once you set up the cut settings (by color, like a laser cutter), you can save the file with those settings. You can also save the file to a USB stick and drive the printer directly with that -- no computer needed!

Why I'm interested

This machine is fast and cheap enough that I think we could use it for small runs of manufacturing. Running it from a USB stick means you could drive several at the same time and switch jobs quickly. It does consume blades and cutting mats, but they're not too expensive.

Interestingly, it also holds pens, and ships with a set of silver, gold, and white gel pens. I've also seen DIY pen holders posted on Thingiverse. Cut size is 12" x 10 feet! And there's a more expensive version called the Curio which can cut much thicker material, etch metal, and hold two cutting tools at once.

Follow related tags:

spectrometer oil-testing-kit papercraft paper

Testing the Oil Testing Kit: identifying a "somewhat unknown" sample

I finally made time to test @mathew's prototype Oil Testing Kit attachment for the Public Lab Spectrometer v3.0, and here are my results.

The basic procedure I followed was:

- prepare all provided samples

- scan each one

- choose an "unknown" from them, prepare in the same way

- compare to known samples to try to figure out what the unknown is

This went well, although not perfectly. We'd expected that we'd be able to tell crude oil from diesel and various motor oils, but that distinguishing motor oils might be difficult. But our eventual goal is to distinguish crude oil from other petroleum types as well as from other kinds of false positives.

The knowns

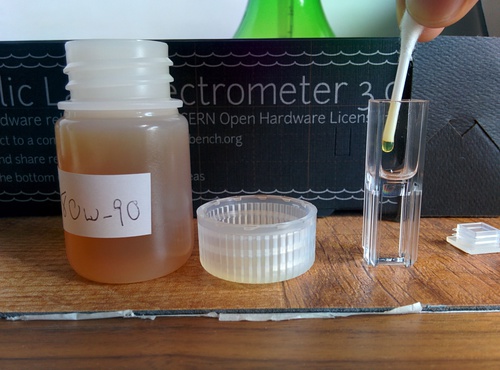

I generally followed the steps outlined in @mathew's original test, which predates the new OTK attachment. The attachment made this test much much easier, but there were still a few hiccups. I began by scanning each of the provided samples, pictured above. They are, in order of "weight":

- Diesel fuel

- 5W30 oil

- 20W50 oil

- 80W90 oil

- North Dakota crude oil (from ONTA)

This went well, although I noted that it took quite a while for the oils to evenly distribute into the ~10ml of mineral oil in the PMMA/acrylic cuvettes. (These and many other supplies are included in the Oil Testing Kit.) I also had only one eyedropper, which I kept clean (mineral oil only) and I used cut-in-half cotton swabs to transfer drops of sample into the cuvettes. I used the plastic tube end, not the cotton end, and some samples were more viscous than others and easier to get drops of -- the diesel was hard, for example. And of course, I used a fresh swab for each oil!

Quantities

When I first tried to scan them in using the new OTK frame (pictured), some of the samples didn't fluoresce strongly enough to get an overall brightness between 25-75%, as we recommend in the Oil Testing Kit docs. However, I just added more drops until they were bright enough. I didn't actually have to use the attenuator strip provided, but it's nice to know it's available for fine-tuning the exposure. I had to add:

- one tiny drop (1/4 of a drop?) of the crude (or it'd have been too dark -- this fluoresces like crazy, so it was fine)

- 3 drops of 5w30 and 20W50 oil

- 4 drops of 80W90

- 8 drops of diesel

Note that the amounts don't seem to correlate with the weight of the samples -- or if they do, 80W90 bucks the trend as presumably the heaviest motor oil, but needing more than the lighter 5W30 and 20W50.

Here's what they look like, raw. (link to set here) I calibrated them all, smoothed them with the "auto-smooth 10 pixels" feature in the More Tools menu, and added them to a set. I did choose cross sections that did not have very bright laser peaks at ~400nm, although there are still some in the motor oils (5W30,20W50, and 80W90).

The differing amounts of sample could be a concern in the differences between our data, but they don't correlate with anything in particular. I don't think, for example, that we're just seeing a trend due to the concentration, as the spectra with the most drops are still the ones with the weakest spectra, despite the fact that adding drops increases brightness.

What we do see is that generally, the crude is out to the right, with longer wavelengths, and that as the oils are lighter, they have a less pronounced "hump" at around 470 nanometers. The humps themselves, or rather the dip preceding the hump at about 450nm, may be an artifact of the blue and green curves meeting in a kind of "saddle" between peaks -- each is detected in different cells of the Bayer filter -- but generally a larger hump indicates that the data skews right.

The unknown

It was impractical (nobody's here to help!) to completely blindly choose a sample, so I turned the bottles around and chose one of the orangish ones, which look pretty much the same unlabeled. I can clearly tell the diesel and crude, but those are supposed to be the easist to distinguish anyhow, so my narrower "blind" test is a harder challenge.

I picked one, prepared it (five drops, since that's what 2/3 of the middle-weight oils needed, so it's a reasonable guess) and scanned it in. In the set embedded above, you can see the unknown alongisde the other samples, but as we found in our work last summer and improved on last fall, it's very helpful to equalize either the maximum height OR the area under each curve, for comparison. This is complicated by the spike from the laser light, but when you equalize area, this is what you see:

From looking at both graphs, a few things are apparent.

- the new embed graphs are WAY more readable, so I look forward to finishing my work on that so the analysis page is easier to read and use

- on the raw, unequalized graph, the unknown fell between 20W50 and 80W90

- on the equal area graph, from visual examination, it seems to be most similar to 80W90

- in both graphs, it was clearly quite different from diesel and crude

The laser spike was a big problem -- it throws off the height equalization and likely the equalize area adjustments too. I realized that we should have a means to equalize area only between 410-700 nanometers, just the way we created the "find graph center" in our work last fall. I'll see about making a macro to do that, soon. For a look at some published research @mathew and I looked at while developing this comparative method, and about a technique we found for grading by graph center, read this note.

Still, my best guess was that it was 80W90, with 20W50 as a second guess. I turned the bottle around, and it was 20W50 -- so my guess wasn't perfect, but it was easy to tell that it wasn't crude.

Next steps

So, pretty good, but there are some clear things we can do next to improve:

- bracket the equalize-height and equalize-area tools to 410-700nm to avoid the effects of the laser peak on these adjustments

- complete my work on the new graphing interface and display to improve readability

- possibly standardize our guidelines for how much sample to add to a cuvette full of mineral oil

Thanks, any comments/critiques welcome -- esp. noting things I've overlooked!

Follow related tags:

spectrometer laser fluorescence crude

Announcing the Oil Testing Kit Public Beta Program

You may have seen hints of this across the site in recent weeks, but today, Public Lab is formally launching the new Oil Testing Kit Public Beta Program. This is an exciting opportunity to help improve our prototype DIY methods for classifying unknown petroleum samples. Our eventual goal is for this kit to be usable to test and compare oil spill residues, and we need your help!

Public Lab is offering the new 3.0 version of our Desktop Spectrometry Kit, plus a prototype version of the new Oil Testing Kit attachment, free of charge for 20 people who can commit to test and offer feedback on the kit.

In exchange for the free kits, Beta Program members will be required to:

- Post ‘unboxing’ and ‘finished assembly’ photos on Twitter.

- Post feedback on the kit and sample preparation methods in one or more research notes at PublicLab.org

- Create and post a set of spectra from the samples sent with the kit (see more detail here)

- Share and discuss input and suggestions on ways to improve the kit on Public Lab’s “plots-spectrometry” mailing list

- Attend two meetups with other Beta Kit Participants online (to be announced soon)

The Beta Program will be run by Public Lab Fellow Yagiz Sutcu, leave a comment below with your questions!

Learn more about the Beta Program and apply here!

Follow related tags:

spectrometer oil-testing oil-testing-kit homebrew-oil-testing-kit

Sprint Fellowship Application: Public Lab Oil Sheen Testing

Application due: September 25, 2015

Dates of Fellowship: mid-October 2015 to mid-January 2016

Location: Remote, with preference for Portland (OR), Boston area, New Orleans or Raleigh-Durham

Fellowship stipend: $3,000 USD

With the Public Lab Oil Testing Kit, we have been working with up to grade prepared samples and have a test that works in a controlled setting. We need your help taking this test into the field to collect oil on water -- this fellowship will support a community researcher to explore and pioneer techniques for collecting and concentrating oil sheens from the surface of bodies of water for analysis in the Oil Testing Kit.

Methods published (primarily on the PublicLab.org site) during this fellowship should avoid hazardous chemicals and utilize widely available, low-cost equipment in order to ensure that the techniques are accessible to members of the public without special equipment or expertise. The fellow will design and conduct sample preparation experiments, document experimental results, and write protocols for appropriate techniques.

The fellow should have a background in chemistry, with environmental chemistry and analytical chemistry experience preferred. The fellow should have experience conducting independent laboratory-based studies and be familiar with data quality assurance and quality control metrics. The fellow will work closely with the Data Ambassador and the Director of Production throughout the fellowship tenure, and will have support particularly in study design, material sourcing, and trouble-shooting.

Successful completion of this fellowship will produce:

- A robust and easily replicable sample preparation method for analysis of oil sheens using the Public Lab Oil Testing Kit

- Documentation of trial methods, successes and failures on the Public Lab website

- A collection of spectra from experimental sample analysis, published on Spectral Workbench

- Integration of the documented techniques with the upcoming Spectral Workbench 2.0 (e.g. through guides or wizards).

- Coordination with three contributors to independently test the developed methods

Follow related tags:

oil-testing-kit fellows response:11752 first-time-poster

Oil Testing Kit -- mixing 5W30 20W30

What I want to do

Since the oils in the Oil Testing Kit 5W30 and 20W50 are distinguishable by their fluorescence spectra (see Research Note: http://publiclab.org/notes/gretchengehrke/07-10-2015/oil-testing-kit-discerning-5w30-20w30), I wanted to see if a 1:1 mixture of the two oils would have a fluorescence spectra with bimodal lambda-max values that would align with the lambda-max value of each neat oil.

My attempt and results

I used the gradation on the eye droppers to mix equal parts 5W30 and 20W50 in an independent glass container (a shot glass, empty of course) and then used a new eye dropper to agitate the oils into a homogeneous mixture and transfer the mixture into a new cuvette.

I took a new white light spectra for this session's calibration, and then took the spectra of the mixture, neat 20W50, and neat 5W30. I used the new white light spectra to calibrate the sample spectra, smoothed each spectra, and equalized the peak heights. https://spectralworkbench.org/sets/show/2439

The mixture does indeed have bimodal lambda-max values, and they do align with the lambda-max values of each neat oil. Awesome!

I do wonder whether or not we would be able to discern the end-members of the mixture without direct comparison to neat products in this same analytical session. I doubt it, simply because of peak overlap. I will try comparing spectra across days and different ambient conditions.

Questions and next steps

The next step is to do triplicate analyses to observe replication/precision. I also want to compare spectra of the same samples across days and using different calibrations.

Why I'm interested

Oil Testing Kit -- we want to know the precision and the ability to discern oils and mixtures of oils. Also, we need to know how fluorescence intensity of different samples impacts their mixtures' spectra (i.e. if you have a 1:1 v:v mixture of oils, but one has a much stronger intensity than the other, how could you tell from the resultant mixture spectra what the mixture ratio is?)

Follow related tags:

spectrometer oil oil-testing oil-testing-kit